In the hectic

world of modern-day manufacturing and innovation, the search for products that can hold up against severe conditions while offering phenomenal efficiency is ever-present. Among the myriad alternatives readily available, polyimide has become a standout supermaterial, catching the focus of sectors varying from aerospace and auto to electronic devices and clinical tools. Its one-of-a-kind mix of high thermal stability, chemical resistance, and mechanical homes makes polyimide a suitable option for applications demanding reliability under pressure. The convenience of polyimide is really remarkable, as seen in

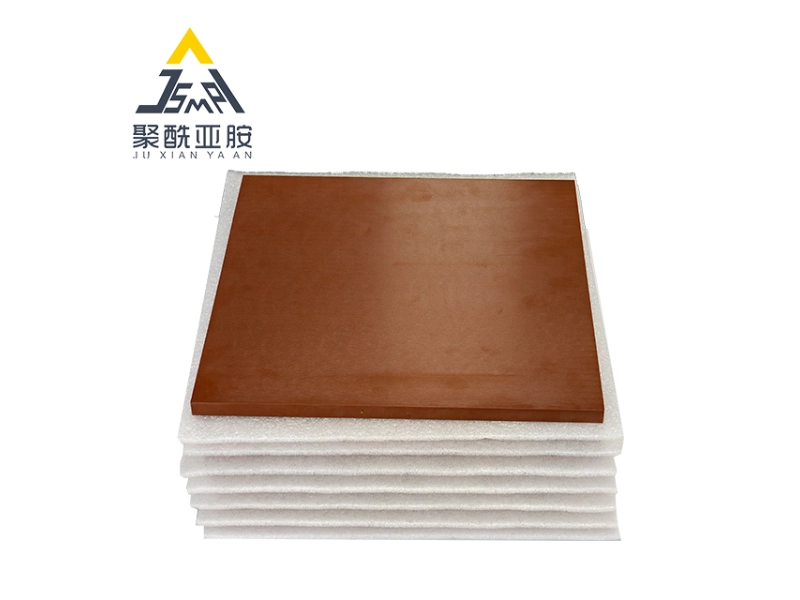

items like polyimide rods and PI engineering plastics. These materials not just supply exceptional performance yet likewise open doors to innovative layouts and options. As markets remain to advance and encounter new obstacles, polyimide will undoubtedly play an essential duty fit the future of advanced products and applications. What is Polyimide? Polyimide is a high-performance polymer known for its remarkable thermal security, mechanical toughness, and chemical resistance. It is a versatile material that can hold up against extreme temperature levels, making it an excellent selection for applications in markets such as aerospace, electronic devices, and automotive. The unique chemical framework of polyimide allows it to keep its residential properties over a vast array of temperature levels, from cryogenic to over 300 degrees Celsius. This supermaterial is available in various types, consisting of layers, films, and poles. Polyimide rods are especially useful in

applications where high stamina and longevity are needed. These poles can be machined to accurate measurements and are immune to put on and chemicals, making them suitable for use in bearings, insulators, and bushings. The versatility in form variable enables customization in different design services. Polyimide is also acknowledged for its outstanding dielectric residential or commercial properties, which make it an exceptional option for the electronics sector. In the production of flexible

printed circuit boards and insulation materials, polyimide pi plastic is made use of for its capacity to withstand high voltages while preserving structural stability. As an outcome, polyimide has come to be an important product in the growth of innovative innovations throughout various markets. Applications of Polyimide Rods Polyimide rods are significantly utilized in the aerospace sector as a result of their remarkable thermal stability and mechanical strength. The capacity to endure high temperatures makes them ideal for applications in engine parts and insulation products. Designers

count on these poles for their light-weight buildings, which add to sustain performance and general performance in aerospace lorries. In the electronic devices sector, polyimide rods serve a vital duty in the production of insulation parts and circuit card. Their dielectric homes allow them to resist electric failure, making them suitable for high-frequency applications. As devices end up being much more performance-oriented and compact, the demand for polyimide rods continues to climb, offering suppliers with reputable and sturdy products. Furthermore, polyimide rods discover applications in the production of industrial elements, such as bearings, seals, and gears. Their resistance to wear and chemical exposure makes certain durability in difficult environments, making them a preferred choice in various machinery and tooling applications. Industries take advantage of the one-of-a-kind mix of residential or commercial properties supplied by polyimide, which converts right into higher performance and lowered maintenance prices. Benefits of Polyimide Pi Plastic Polyimide Pi Plastic is renowned for its exceptional thermal security, which makes it a suitable selection for applications that require materials to stand up to high temperatures. This property enables polyimide to maintain its structural stability and performance also in tough settings, exceeding lots of standard

plastics. As markets promote elements that can operate effectively at elevated temperature levels, polyimide exemplifies an exceptional choice. One more significant benefit of polyimide is its remarkable chemical resistance. PI Polyimide Plastic can stand up to a broad variety of chemicals, including gas, solvents, and oils, which is essential for components used in aerospace, automobile, and electronic devices applications. This durability makes certain that polyimide retains its buildings and capability, decreasing the requirement for regular maintenance or replacement, which can lead to cost financial savings and enhanced dependability. Polyimide Pi Plastic uses excellent dielectric properties, making it well-suited for electrical insulation applications. Its capability to preserve high insulation resistance makes it a favored material in the electronics market, especially for motherboard and components that call for dependable efficiency under electric tension. As demand for high-performance materials increases, polyimide remains to verify

its worth as a trustworthy and versatile selection across different industries. Future of PI Engineering Plastics The future of PI design plastics looks extremely encouraging as markets continue to look for products that can meet extensive performance standards. With developments in making innovations, such as 3D printing and injection molding, polyimide's special properties can be harnessed to produce components that are lighter, more powerful, and able to endure severe temperature levels. This development will certainly make it possible for a broader variety of applications, particularly in aerospace and automobile markets, where material performance

is crucial. Sustainability is an additional driving force in the development of polyimide usage. As https://www.instapaper.com/p/15878047 expand, there is a significant push in the direction of establishing green options and recycling processes for PI design plastics. Research is underway to enhance biodegradability and lower the carbon impact related to polyimide production. This pivot in the direction of lasting products will not only assist markets adhere to regulations but additionally advertise a more eco accountable strategy to product selection.

Last but not least, the expanding pattern towards miniaturization in innovation will certainly additionally sustain the need for polyimide pole and various other kinds of PI engineering plastics. As digital devices end up being a lot more small, the need for high-performance products that can operate successfully within tight rooms and high warmth environments comes to be increasingly crucial. The versatility of polyimide makes it an ideal candidate for these ingenious applications, solidifying its function as a crucial supermaterial in the future landscape of numerous markets.

Its one-of-a-kind combination of high thermal security, chemical resistance, and mechanical residential properties makes polyimide an optimal selection for applications demanding integrity under stress. As sectors continue to progress and encounter new obstacles, polyimide will unquestionably play a pivotal function in shaping the future of sophisticated materials and applications. As a result, polyimide has become an indispensable product in the development of advanced modern technologies across different sectors. As tools end up being much more small and performance-oriented, the demand for polyimide poles proceeds to increase, offering manufacturers with reliable and long lasting products. Polyimide Pi Plastic is renowned for its remarkable thermal stability, which makes it an optimal selection for applications that require materials to stand up to high temperature levels.