In the mission for sophisticated products that can stand up to extreme conditions while preserving exceptional efficiency, polyimide(PI)plastic has actually arised as a frontrunner. Recognized for its impressive thermal stability, chemical resistance, and mechanical residential properties, PI plastic is swiftly acquiring grip across various markets, from aerospace to electronic devices and past. As the need for high-performance materials continues to expand, the fostering of PI engineering plastics is not simply a fad yet a transformative shift toward a lot more effective and resilient remedies. The ingenious capacities of PI polyimide plastic open new doors

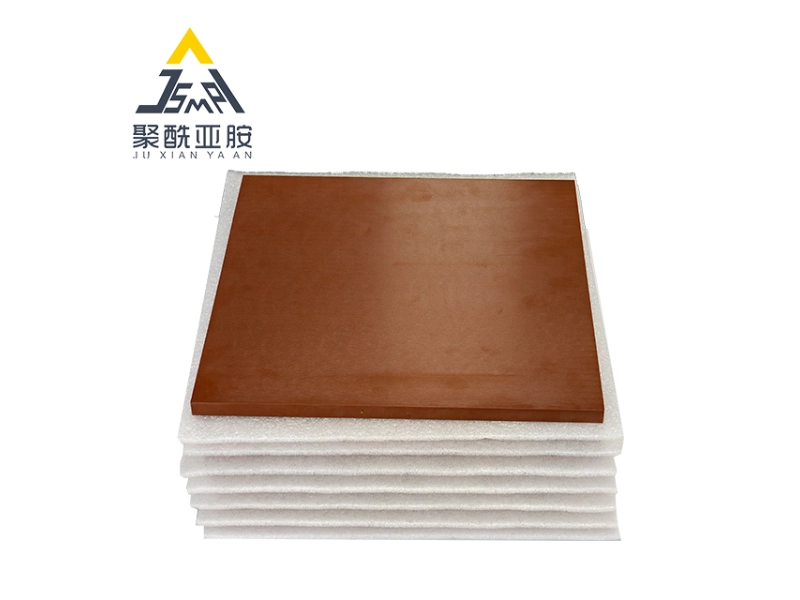

for applications that need products to sustain extreme environments and strenuous functional needs. Its unique framework allows it to function efficiently at both low and high temperatures, making it appropriate for a range of uses, consisting of adaptable electronics, insulation, and even room expedition. As even more industries recognize the advantages of PI plastic, we are on the precipice of a brand-new era where high-performance products redefine the limitations of what is feasible. What is Polyimide PI Plastic? Polyimide PI plastic is a high-performance polymer understood for its remarkable thermal security and mechanical residential properties. Its one-of-a-kind framework permits it to stand up to extreme temperatures, making it suitable for applications in aerospace, electronic devices, and automotive markets. The adaptability of polyimide plastics appears in their broad variety of kinds, consisting of films, sheets, and formed components, which can be customized to satisfy particular efficiency needs. The chemical structure of polyimide is what establishes it apart from other design plastics. It is formed through a condensation response in between aromatic dianhydrides and diamines, leading to a secure and strong polymer foundation. This structure not just offers exceptional thermal resistance yet likewise exceptional chemical resistance, enabling polyimide products to carry out well in rough settings that would certainly break down various other plastics. In addition to their chemical and thermal resilience, polyimide PI plastics display impressive mechanical residential properties, such as high tensile stamina and versatility. These characteristics make them suitable for a variety of requiring applications

, including insulating materials in electrical devices and components in high-temperature machinery. As http://www.drugoffice.gov.hk/gb/unigb/www.hsjuxin-pi.com/ proceed to seek light-weight and durable materials, polyimide plastics stick out as a promising remedy for the future of high-performance materials. Applications of PI Engineering Plastics PI engineering plastics have located widespread applications throughout numerous markets as a result of their exceptional thermal security and mechanical properties. In the aerospace industry, these products are used for parts that must endure extreme temperatures and rough atmospheres. Their lightweight nature together with high warmth resistance makes them perfect for components in airplane engines and various other important systems, boosting safety and efficiency. The electronics sector additionally leverages PI polyimide plastics for protecting products in adaptable motherboard and adapters. Their superb dielectric residential properties and ability to maintain performance under high thermal stress and anxiety make them a favored option for applications varying from customer electronic devices to innovative army gadgets. As electronic components end up being progressively miniaturized, the

need for lightweight and reliable protecting products remains to grow. Additionally, PI plastic is making considerable invasions in the automotive market, where it is utilized in a range of applications including seals, gaskets, and other components that need longevity under high temperatures and direct exposure to chemicals. The need for a lot more ecologically pleasant and reliable materials in automobile production sustains the enhanced use PI engineering plastics, ensuring that cars are both light-weight

and efficient in meeting government regulations on exhausts and safety and security. Advantages of PI Polyimide Materials PI polyimide materials use extraordinary thermal stability, permitting them to carry out properly in extreme temperature conditions. This residential property makes them excellent for applications in aerospace, electronics, and various other markets where materials need to stand up to high heat. Unlike typical plastics, which might degrade or lose honesty under such problems, PI plastics keep their mechanical homes and reliability, ensuring durable performance. An additional considerable benefit of PI polyimide is its superb chemical resistance. These products can endure direct exposure to a variety of solvents, acids, and bases, making them appropriate for environments where chemical rust is a worry. This durability enhances the durability of components and systems that count on PI design plastics, eventually reducing maintenance and replacement prices over time. PI polyimides exhibit outstanding electrical insulation buildings. They are used thoroughly in the electronics market to insulate cords, wires, and elements

. With their remarkable dielectric strength, PI plastics assist in avoiding electric failings and improving the general security and performance of electronic gadgets. This combination of thermal stability, chemical resistance, and electrical insulation settings PI polyimide products as a leading selection in high-performance applications. Future Trends in High-Performance Plastics As sectors remain to demand products that use both longevity and versatility, the future of high-performance plastics is increasingly concentrated on innovations in polyimide PI plastic. With remarkable thermal security, chemical resistance, and mechanical buildings, PI polyimide plastic is anticipated to take spotlight in fields such as aerospace, auto, and electronic devices. The capacity of polyimide products to work properly in extreme problems positions them as perfect prospects for sophisticated applications, leading the means for research and growth in their solution and production. Sustainability is likewise ending up being an important consideration in the development of PI design plastics. As ecological regulations tighten up and the push for greener options strengthens, makers are checking out bio-based polyimide remedies and reusing approaches for PI plastics. The combination of sustainable techniques in the production of high-performance products not just meets governing needs however additionally attract an expanding eco-conscious consumer base, thereby influencing the design and lifecycle of polyimide products. The electronic improvement of making processes is an additional trend poised to reinvent the manufacturing of high-performance plastics. The adoption of additive manufacturing methods, such as 3D printing,

permits the creation of complex geometries that were previously challenging to achieve with conventional methods. This technological improvement allows more effective use of products and reduces waste, while additionally opening brand-new opportunities for modification in PI polyimide applications. As these patterns converge, the future of high-performance plastics appears bright, driven by advancement and a commitment to sustainability. Introducing PI Plastic: The Future of High-Performance Materials.xxx.In the pursuit for innovative materials that can endure severe problems while maintaining outstanding performance, polyimide(PI)plastic has actually emerged as a frontrunner. Polyimide PI plastic is a high-performance polymer recognized for its phenomenal thermal stability and mechanical properties. https://independent.academia.edu/AlexandersenPape5 for insulating materials in adaptable circuit boards and connectors. Unlike typical plastics, which might deteriorate or shed integrity under such problems, PI plastics maintain their mechanical residential or commercial properties and dependability, making certain lasting performance. As industries proceed to require materials that use both durability and flexibility, the future of high-performance plastics is progressively concentrated on developments in polyimide PI plastic.